Products

DFY type wear resistant self vibration anti blocking sampling device

DFY self vibration and wear-resistant type attempts to prevent the pressure sampling device: DFY-05 type Sampling Device. This device uses special materials to solve the problem of dynamic pressure probe and the use of continuous wear and tear from vibration device and a special structure to solve the congestion problem of the probe, greatly improving the air (dust) of the flow line measurement accuracy and reliability. Widely used in coal-fired power plant boiler one, two, three air pressure line monitoring.

Product Description

1. Overview

DFY self vibration and wear-resistant type attempts to prevent the pressure sampling device: DFY-05 type Sampling Device.

This device uses special materials to solve the problem of dynamic pressure probe and the use of continuous wear and tear from vibration device and a special structure to solve the congestion problem of the probe, greatly improving the air (dust) of the flow line measurement accuracy and reliability. Widely used in coal-fired power plant boiler one, two, three air pressure line monitoring.

The device is a fundamental solution to the boiler in the presence of cross-wind component wear and attempts to prevent the two key technologies.

Using the special structure of the self-cleaning structure of anti-vibration plug, eliminating the complexity of laying gas pipelines and gas sources, saving the cost of investment and reduce the amount of routine maintenance.

Sampling some of the use of special wear-resistant material at high temperature sintering process can be long-term use.

At present, coal-fired power plant operating personnel to run operations are almost always based on the total pressure, current, and adjust the fan baffle opening, to the powder machine speed, a wind static pressure and other parameters to organize and adjust combustion. This traditional method of operation, the true wind speed for the level of boiler operation, air volume, and uniformity, the size of pulverized coal concentration and uniformity of effective monitoring is not straightforward to quantify. Thereby directly affecting the boiler combustion stability, economy and security and reliability. Wind speed as an air duct caused by plugging too easily, too easy to produce combustion instability, severe wear powder feeding tube, the combustion efficiency is low, uneven corners of the burner with the wind, the flame deflection furnace wall erosion, resulting in partial slagging and heat load caused by excessive local pipe explosion.

As the boiler during operation in the actual existence of a range of issues, such as the erosion flame furnace wall deflection in the local area near the furnace wall, a strong reducing atmosphere resulting from water-wall corrosion or coking local temperature, heat load is uneven, the flue gas side and steam side temperature deviations can not be optimized to run low Nox, high carbon content of fly ash problems affecting the reliability of plant operation and economy. Tangentially burner for its biggest feature is the four air jets mutual support and stability on fire after fire, air, after intersecting strong rotation, gas heat, momentum exchange is very strong. Tangentially to a strong jet turbulent diffusion furnace power and good results. To achieve this objective requires the four corners of the layers one, two, three times the amount of wind the wind the same, the same amount of coal into the furnace. Otherwise, there will be four-stranded air jet intersection (tangentially) deviate from the design point, one side furnace wall, increasing water-wall coke.

In order to run the boiler to reach an ideal state as far as possible, once, twice, three air pressure line monitoring of utmost importance. The amount of use of the on-line monitoring devices, by adjusting the throttle opening, making the burner air distribution has been optimized boiler operation can greatly improve the safety and economy, to avoid burning the burner, the water wall, or other areas of coke, the heat load is not are caused by burst pipes, high temperature reducing atmosphere to avoid corrosion and other issues.

2.Performance and excellent features

High accuracy up to ± 3%

No gas supply, eliminating the gas pipeline, saving the cost of investment

Device is not throttling device, does not increase the resistance of the piping system under test

Special structure of the probe with self-cleaning unit, plug the long-running problem-free

The probe uses a special wear-resistant materials, wear long-running problem-free

System is simple, easy installation, renovation work is small, reliable operation

Changes will not affect coal composition

Wide application and can be used for a variety of coal supply and transportation pipeline system.

The boiler with a reasonable wind, burning more stable, can effectively reduce exhaust gas temperature, reducing the carbon content of fly ash to reduce the mechanical and chemical coal incomplete combustion heat loss and improve boiler efficiency.

Can reasonably adjust the proportion of pulverized.

Can effectively prevent plugging or off the pink phenomenon.

Can effectively control the boiler flame center, to prevent the local coke boiler, but also can effectively prevent the flame deflection, lower flue gas temperature furnace together on both sides of the deviation of exports. Prevent the water wall and superheater tube rupture.

The DC burner, can reasonably determine the first, second and tertiary air ratio and secondary air on the match, middle and lower layers with wind conditions, is now the tower type, inverted pyramidal, or waist-type mode with the wind, etc. fireman at a glance.

Three wind-line monitoring of the implementation of the milling system is equal to the ventilation rate of implementation of online monitoring of the milling system is conducive to the safety and economic operation.

Can greatly reduce the boiler cold air dynamic field test workload.

3.Installation

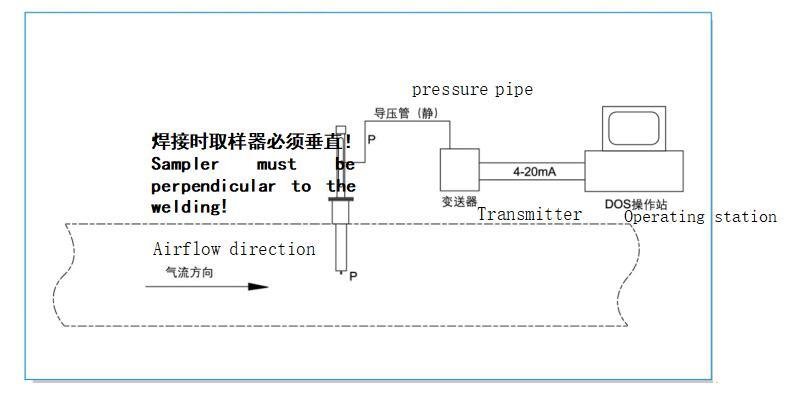

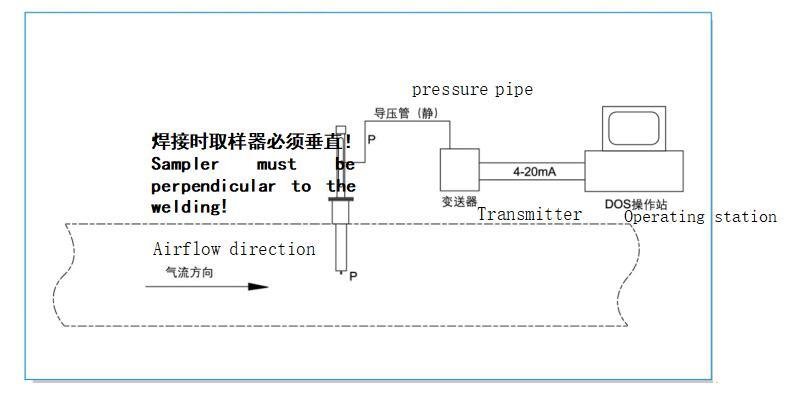

Installation must be in vertical sampling device, in order to achieve optimal production results, shown in Figure 1:

Installation diagram

4. Scope

1.Measuring an air duct, an air vent air pressure;

2.Measuring secondary air pipe, the secondary air nozzle air pressure;

3.Measured in triplicate duct, tertiary air nozzle air pressure;

4.Measurement silos pulverizing system pressure within a duct;

DFY type wear resistant self vibration anti blocking sampling device

DFY self vibration and wear-resistant type attempts to prevent the pressure sampling device: DFY-05 type Sampling Device. This device uses special materials to solve the problem of dynamic pressure probe and the use of continuous wear and tear from vibration device and a special structure to solve the congestion problem of the probe, greatly improving the air (dust) of the flow line measurement accuracy and reliability. Widely used in coal-fired power plant boiler one, two, three air pressure line monitoring.

Product Description

1. Overview

DFY self vibration and wear-resistant type attempts to prevent the pressure sampling device: DFY-05 type Sampling Device.

This device uses special materials to solve the problem of dynamic pressure probe and the use of continuous wear and tear from vibration device and a special structure to solve the congestion problem of the probe, greatly improving the air (dust) of the flow line measurement accuracy and reliability. Widely used in coal-fired power plant boiler one, two, three air pressure line monitoring.

The device is a fundamental solution to the boiler in the presence of cross-wind component wear and attempts to prevent the two key technologies.

Using the special structure of the self-cleaning structure of anti-vibration plug, eliminating the complexity of laying gas pipelines and gas sources, saving the cost of investment and reduce the amount of routine maintenance.

Sampling some of the use of special wear-resistant material at high temperature sintering process can be long-term use.

At present, coal-fired power plant operating personnel to run operations are almost always based on the total pressure, current, and adjust the fan baffle opening, to the powder machine speed, a wind static pressure and other parameters to organize and adjust combustion. This traditional method of operation, the true wind speed for the level of boiler operation, air volume, and uniformity, the size of pulverized coal concentration and uniformity of effective monitoring is not straightforward to quantify. Thereby directly affecting the boiler combustion stability, economy and security and reliability. Wind speed as an air duct caused by plugging too easily, too easy to produce combustion instability, severe wear powder feeding tube, the combustion efficiency is low, uneven corners of the burner with the wind, the flame deflection furnace wall erosion, resulting in partial slagging and heat load caused by excessive local pipe explosion.

As the boiler during operation in the actual existence of a range of issues, such as the erosion flame furnace wall deflection in the local area near the furnace wall, a strong reducing atmosphere resulting from water-wall corrosion or coking local temperature, heat load is uneven, the flue gas side and steam side temperature deviations can not be optimized to run low Nox, high carbon content of fly ash problems affecting the reliability of plant operation and economy. Tangentially burner for its biggest feature is the four air jets mutual support and stability on fire after fire, air, after intersecting strong rotation, gas heat, momentum exchange is very strong. Tangentially to a strong jet turbulent diffusion furnace power and good results. To achieve this objective requires the four corners of the layers one, two, three times the amount of wind the wind the same, the same amount of coal into the furnace. Otherwise, there will be four-stranded air jet intersection (tangentially) deviate from the design point, one side furnace wall, increasing water-wall coke.

In order to run the boiler to reach an ideal state as far as possible, once, twice, three air pressure line monitoring of utmost importance. The amount of use of the on-line monitoring devices, by adjusting the throttle opening, making the burner air distribution has been optimized boiler operation can greatly improve the safety and economy, to avoid burning the burner, the water wall, or other areas of coke, the heat load is not are caused by burst pipes, high temperature reducing atmosphere to avoid corrosion and other issues.

2.Performance and excellent features

High accuracy up to ± 3%

No gas supply, eliminating the gas pipeline, saving the cost of investment

Device is not throttling device, does not increase the resistance of the piping system under test

Special structure of the probe with self-cleaning unit, plug the long-running problem-free

The probe uses a special wear-resistant materials, wear long-running problem-free

System is simple, easy installation, renovation work is small, reliable operation

Changes will not affect coal composition

Wide application and can be used for a variety of coal supply and transportation pipeline system.

The boiler with a reasonable wind, burning more stable, can effectively reduce exhaust gas temperature, reducing the carbon content of fly ash to reduce the mechanical and chemical coal incomplete combustion heat loss and improve boiler efficiency.

Can reasonably adjust the proportion of pulverized.

Can effectively prevent plugging or off the pink phenomenon.

Can effectively control the boiler flame center, to prevent the local coke boiler, but also can effectively prevent the flame deflection, lower flue gas temperature furnace together on both sides of the deviation of exports. Prevent the water wall and superheater tube rupture.

The DC burner, can reasonably determine the first, second and tertiary air ratio and secondary air on the match, middle and lower layers with wind conditions, is now the tower type, inverted pyramidal, or waist-type mode with the wind, etc. fireman at a glance.

Three wind-line monitoring of the implementation of the milling system is equal to the ventilation rate of implementation of online monitoring of the milling system is conducive to the safety and economic operation.

Can greatly reduce the boiler cold air dynamic field test workload.

3.Installation

Installation must be in vertical sampling device, in order to achieve optimal production results, shown in Figure 1:

Installation diagram

4. Scope

1.Measuring an air duct, an air vent air pressure;

2.Measuring secondary air pipe, the secondary air nozzle air pressure;

3.Measured in triplicate duct, tertiary air nozzle air pressure;

4.Measurement silos pulverizing system pressure within a duct;

Related Products

Message

Address:No. 107, Luzhong South Road, Yangshan Town, Wuxi City, Jiangsu Province

Fax:0510-83951530

E-mail:hddzyb@163.net

E-mai:hddzyb@vip.tom.com

Scan it follow us

Copyright © 2022 Wuxi Huadong Power Station Automation Instrument Co., Ltd. Website building:www.300.cn 苏ICP备2023028152号-1